Biochar from Biogas Waste Improves Methane Production from Pig Manure

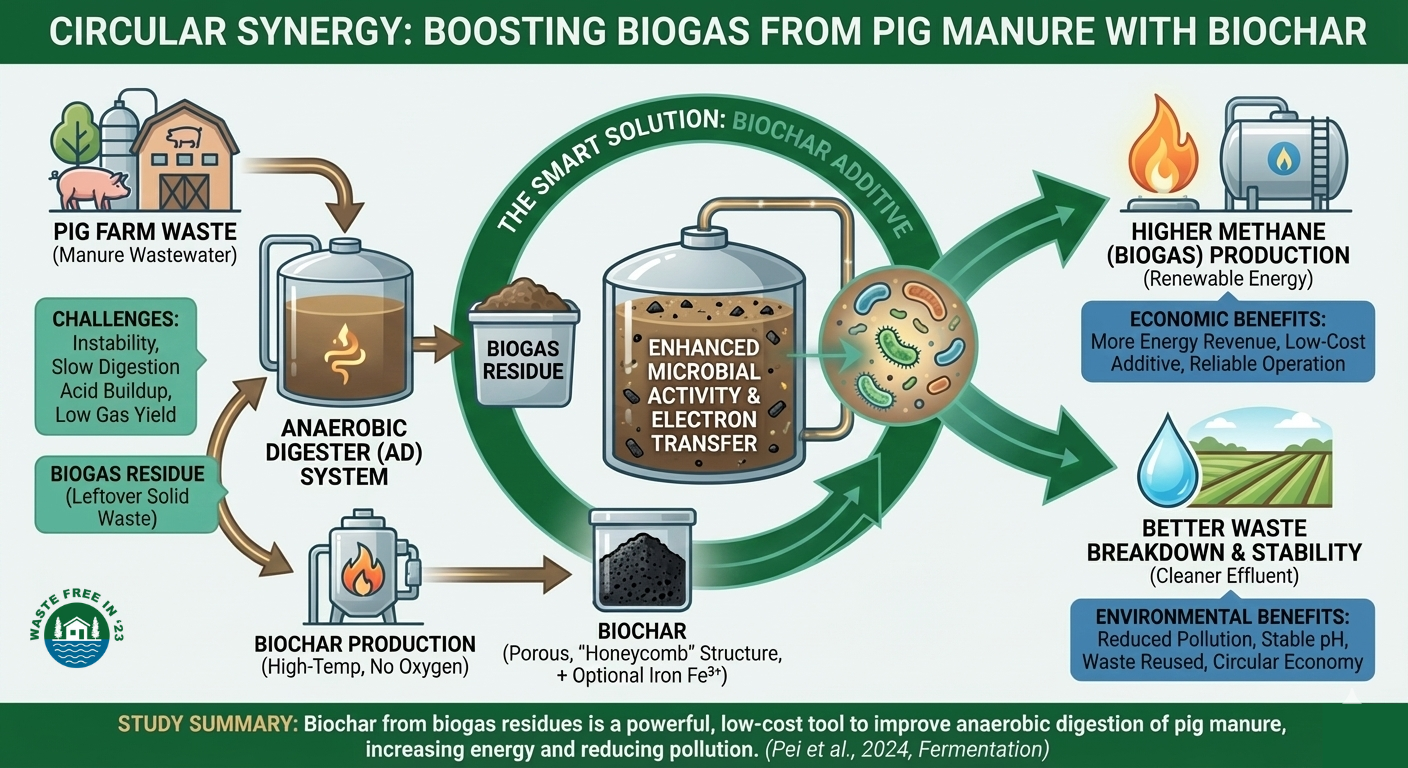

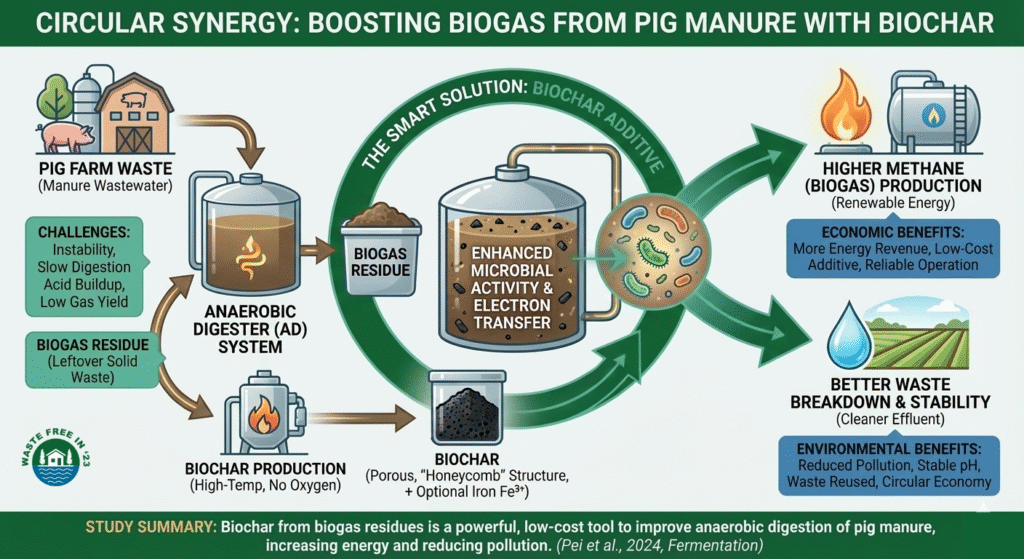

Managing waste from large pig farms is a serious environmental challenge. Pig manure wastewater contains high levels of organic pollution, nutrients, and sometimes antibiotics and heavy metals. If released untreated, it can cause bad odors, water pollution, algae growth, and greenhouse gas emissions. Anaerobic digestion (AD) is commonly used to treat this waste, turning it into biogas (mainly methane) for energy. However, AD systems often suffer from instability, slow digestion, and acid buildup, which reduces gas production.

This 2024 study by Pei et al., published in Fermentation, explores a smart solution: using biochar made from biogas residues to improve the anaerobic digestion of pig manure wastewater.

What the researchers did

The researchers took biogas residue (the solid leftover after anaerobic digestion) and converted it into biochar using high-temperature heating without oxygen. This biochar was then tested in pig manure digestion systems. Some biochar was further modified with iron (Fe³⁺), and results were compared with a commercial iron–carbon material and a control system with no additives.

The digestion experiments were run under controlled conditions, and the researchers measured:

- Methane (biogas) production

- Organic pollution removal (COD)

- Acid buildup (volatile fatty acids)

- pH stability

- Changes in microbial communities

Key environmental benefits

The results showed clear environmental improvements:

- Higher methane production: Systems with biochar and iron additives produced significantly more methane than the control. This means more renewable energy from the same amount of waste.

- Better waste breakdown: Organic pollution removal increased by up to 15%, meaning cleaner effluent and lower environmental risk.

- Reduced acid buildup: Biochar helped microbes consume harmful acids faster, preventing system failure.

- Improved system stability: The digestion process stayed closer to neutral pH, which is ideal for methane-producing microbes.

- Waste reused instead of discarded: Biogas residue, which is often a disposal problem, was turned into a valuable material.

Key economic benefits

From an economic perspective, the findings are highly relevant for farms and waste managers:

- More energy, same waste: Increased methane means more biogas for electricity, cooking gas, or heat — raising revenue.

- Low-cost additive: Biochar was made from waste already produced in digestion systems, reducing material costs.

- Lower operating risk: A more stable digester means fewer shutdowns, less maintenance, and more reliable energy output.

- Scalable for farms: The method can be applied to existing digesters without major redesign.

Why biochar works

Biochar has a porous, “honeycomb-like” structure that provides safe living space for beneficial microbes. It also helps move electrons between microbes, which speeds up methane formation. When iron was added, this effect became even stronger, helping microbes work together more efficiently.

Conclusion

This study shows that biochar made from biogas residues is a powerful, low-cost tool for improving anaerobic digestion of pig manure. It increases renewable energy production, reduces pollution, and turns multiple waste streams into valuable resources. The approach supports circular economy principles and is especially suitable for large-scale livestock farms.

📌 Article Attribution

Pei, Z., Wei, X., Jin, S., Shi, F., Liu, J., Wang, S., Li, P., Luo, Y., Wang, Y., & Wang, T. (2024).

The Enhancing Effect of Biochar Derived from Biogas Residues on the Anaerobic Digestion Process of Pig Manure Water.

Fermentation, 10(12), 644.

https://doi.org/10.3390/fermentation10120644

Got questions?