Biochar SHaCK

Integrating Sustainable Heat Storage with Biochar Production

Introduction

The Biochar SHaCK is an innovative system that combines biochar production with efficient heat storage solutions. This design not only addresses waste management and soil enhancement through biochar but also provides a sustainable method for heat storage and utilization in community settings.

Understanding SHaCK

The SHaCK is a project developed by Waste Free ’23, aiming to offer a zero-fuel, zero-pollution cooking solution that is community-designed, built, and managed. It leverages solar energy to store heat in materials like sand, providing a reliable and sustainable cooking method. For a comprehensive overview, refer to the SHaCK: an Overview page.

What is Biochar?

Biochar is a form of charcoal produced through the pyrolysis of organic waste materials in a low-oxygen environment. This process not only reduces waste but also yields a product that enhances soil fertility and sequesters carbon, contributing to environmental sustainability. In the Biochar SHaCK design, biochar production is integrated, allowing communities to process organic waste efficiently. Read more.

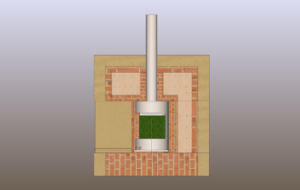

The Biochar SHaCK Design

The Biochar SHaCK integrates the principles of the traditional SHaCK with biochar production, creating a multifunctional system. Key components include:

Sand Heat Battery: Utilizes sand to store heat generated during the biochar production process.

Biochar Production Unit: Incorporates a pyrolysis chamber where organic waste is converted into biochar, releasing heat that is captured by the sand heat battery.

Steam Extraction Tubes: Embedded within the system to harness steam generated during the process, which can be used for cooking or other applications.

Combining Biochar Production with SHaCK

By merging biochar production with the SHaCK system, communities can achieve:

Efficient Waste Management: Transforming organic waste into valuable biochar.

Sustainable Heat Utilization: Capturing and storing heat from the pyrolysis process for cooking and other uses like electricity generation with a steam turbine.

- Soil Enhancement: Producing biochar that can be used to improve soil health and fertility.

👉 Learn how to build a simple, open-source steam turbine generator that converts waste heat from biochar production into electricity using a monotube boiler and Tesla-style turbine:

🔗 DIY Waste-Heat Powered Steam Turbine Generator

Construction Guide

For a detailed, step-by-step guide on building your own Biochar SHaCK, please refer to the following presentation. You can also watch this video guide.

This resource provides comprehensive instructions, ensuring communities can construct and benefit from this sustainable system.

By integrating biochar production with the SHaCK design, communities can harness renewable energy, manage waste effectively, and promote environmental sustainability.

Biochar SHaCK Development

Biochar SHaCKs with steam electric generators are being built in Nairobi, India, Ethiopia, Pakistan, Thailand, and the USA. It is all open-source. Plans are being published, and our team can assist any community or organization working towards a waste-free future.

The Biochar SHaCK project is making significant progress, with global collaboration driving innovation.

Following the building guide and with the help of our qualified engineers, the design is being built up. Previously, a small biochar SHaCK setup was built. The recent goal is to develop a low-cost, open-source steam turbine that can convert biochar SHaCK’s waste heat into usable electricity. Sand battery captures and stores the waste heat which produces steam to produce electricity. Developing small Biochar-SHaCK produces 1 to 5kw electricity.

🔹 Current Developments

✅ Material Procurement & Fabrication

- A 1mm aluminum sheet is being sourced for turbine disks.

- Team members are experimenting with hand-cut disks and using scrap materials for accessibility.

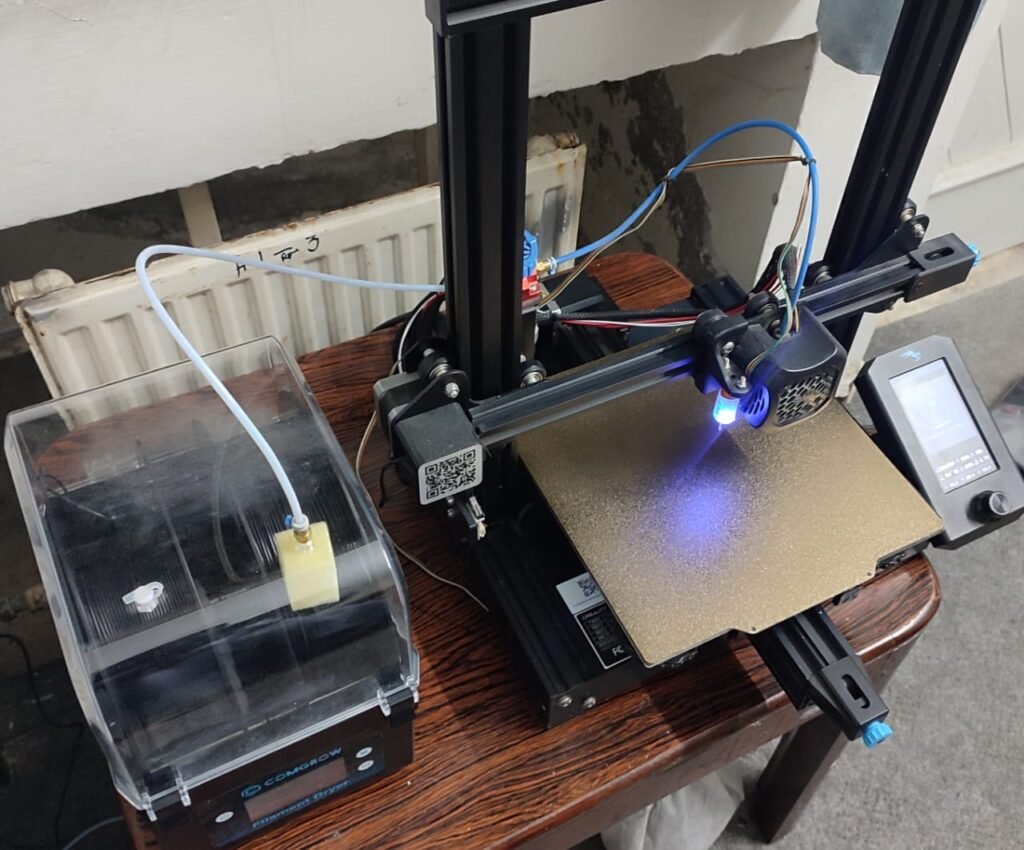

- DIY-style turbine construction is being tested based on monotube boiler systems and bladeless Tesla-style turbines (see our DIY Steam Turbine Generator Guide).

✅ Assembly & Testing

A turbine frame has been assembled and successfully tested using compressed air, confirming smooth rotation.

Steam generation tests are underway, focusing on heat retention, steam pressure, and flow control for safe, efficient performance.

Propane-heated sand is being trialed as a thermal storage medium for continuous steam production.

- A Small Size Biochar SHaCK is set up to get turn biomass into biochar and produce electricity with the steam from the turbine. Below are images of Small Biochar SHaCK Setup with [ 1 ] Exhaust Pipe, [ 2 ] Biomass-Burner Box, and [ 3 ] Steam Tubes.

✅ Technical Improvements

Research is ongoing into 3D-printed turbine blade molds, intended for casting in aluminum or cast iron for higher durability.

Experiments are being conducted on high-pressure water inputs, pressure relief systems, and needle valves to ensure precise steam flow control.

Testing is almost done on temperature sensors, pressure gauges, and other safety mechanisms for reliable operation.

- DIY Tesla Turbine is built and tested successfully, which will reduce the cost and make it possible to implement SHaCK anywhere in the world.

Got questions?