BSFL vs. Biochar: Which Is the Better Way to Turn Organic Waste into Value?

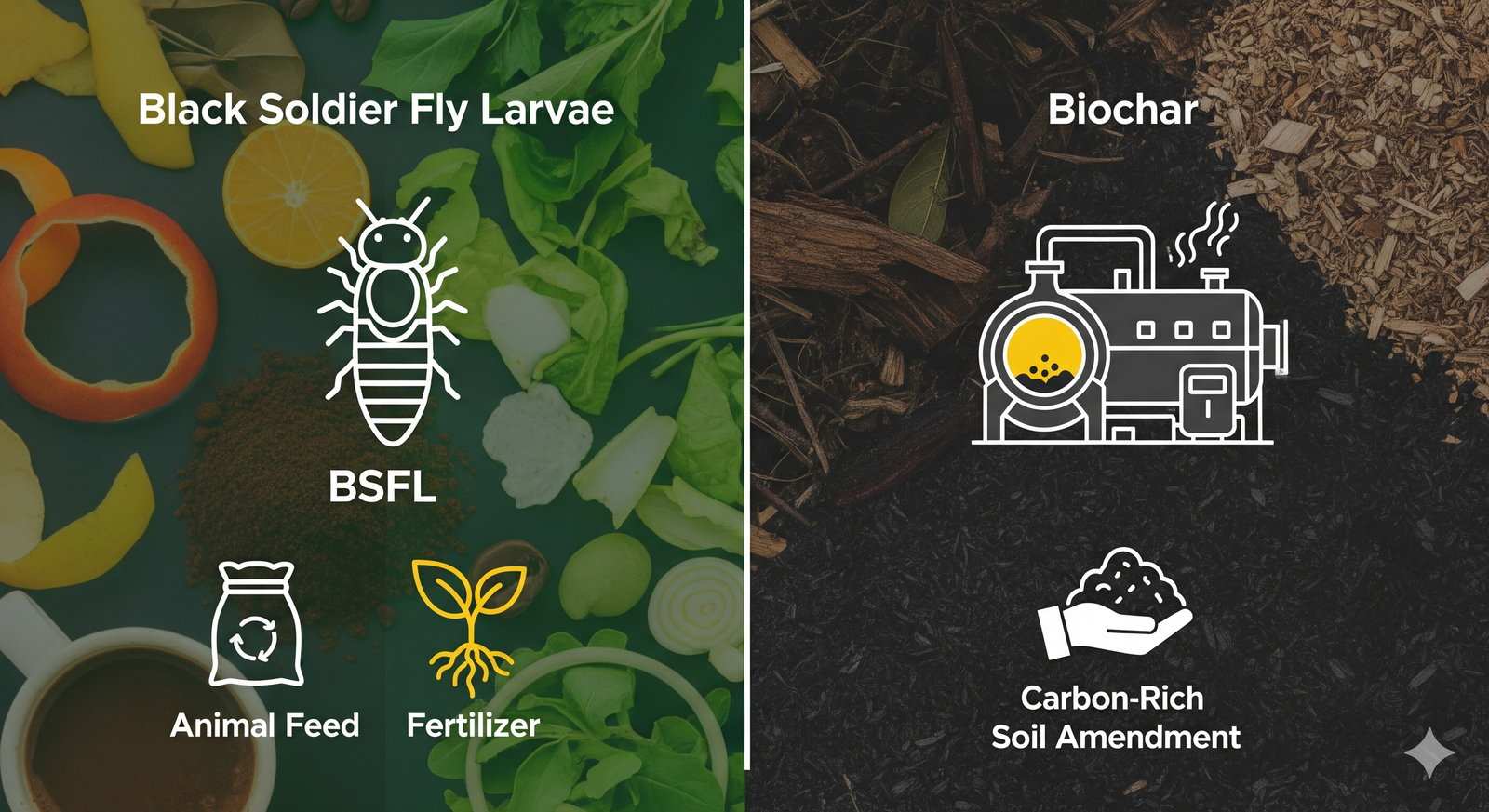

Every year, millions of tonnes of organic waste pile up in cities and farms. Two innovative solutions, Black Soldier Fly Larvae (BSFL) bioconversion and biochar production, are proving that waste is not the end of the line, but the start of new value streams. Both approaches transform biomass into useful products, but in very different ways. The big question: Which one works best for your needs?

What Are BSFL and Biochar?

Black Soldier Fly Larvae (BSFL)

BSFL are tiny biological “machines” that consume food scraps, agricultural waste, and even manure. In just a few days, they turn waste into insect protein and oils (valuable for animal feed) and frass, a nutrient-rich fertilizer. This makes BSFL systems especially attractive for communities dealing with wet, high-moisture organic waste like kitchen scraps or livestock manure (ResearchGate).

Biochar

Biochar is a solid, carbon-rich material produced through pyrolysis, which means heating biomass with little or no oxygen. Farmers have used charcoal-like substances for centuries to improve soils, but modern biochar offers more: it locks carbon away for centuries, improves soil fertility, filters contaminants, and can even qualify for carbon credits (Wikipedia).

Speed of Conversion

- BSFL: Organic waste is reduced by 50–80% within days, making it one of the fastest biological recycling methods (CCAC).

- Biochar: Pyrolysis itself is fast, typically minutes to hours, but the process requires feedstock drying, cooling, and handling, which add time (Wikipedia).

If you want rapid throughput for wet waste, BSFL takes the lead. For woody residues, biochar can be equally efficient once prepped.

Yields and Outputs

- BSFL: From 1 tonne of waste, BSFL can produce insect biomass (protein and fats) and large amounts of frass fertilizer, up to 10–34 tonnes per tonne of larvae produced (ScienceDirect).

- Biochar: Typically yields 20–40% biochar by dry mass, plus syngas and bio-oil that can be used for energy or industrial purposes (Wikipedia).

Product Value and Markets

- BSFL Products:

- Protein and oil for aquaculture, poultry, and pet food.

- Frass fertilizer rich in nutrients and chitin, which boosts soil health.

- Insects have been legally approved in Europe for fish feed since 2017 (EU Feed Rules).

- Protein and oil for aquaculture, poultry, and pet food.

- Biochar Products:

- Soil enhancer for water retention and nutrient cycling.

- Carbon credits as long-term carbon storage is recognized by registries.

- Expanding uses in filtration, construction materials, and pollution cleanup (Wikipedia).

- Soil enhancer for water retention and nutrient cycling.

Environmental Impact

- BSFL:

- Cuts methane emissions from food waste diversion.

- Larvae’s gut microbiome helps degrade pathogens, antibiotics, and even microplastics (The Innovation).

- Cuts methane emissions from food waste diversion.

- Biochar:

- Provides permanent carbon sequestration in soils for decades or centuries.

- Can reduce nitrous oxide emissions by up to 80% and eliminate soil methane release (Wikipedia).

- Provides permanent carbon sequestration in soils for decades or centuries.

Best Feedstocks

- BSFL: Wet, high-organic wastes like food scraps, brewery residues, or manure.

- Biochar: Woody residues, crop wastes, nutshells, pruning materials, and BSFL residue after larvae harvesting.

👉 If your waste is wet and smelly, BSFL thrives. If it is woody or dry, biochar is more efficient.

Cost of Setup and Operations

BSFL systems usually require moderate capital investment in sheds, breeding units, and drying equipment. Operating costs are driven by labor, climate control, cleaning, and feedstock handling, which makes them more labor-intensive but flexible for small to medium setups.

Biochar systems demand higher upfront costs for pyrolysis reactors, dryers, storage, and emission controls. However, once established, they run with lower labor needs, especially if energy co-products are used to offset heating costs.

Scalability

- BSFL: Highly scalable for farms, urban food waste facilities, or decentralized community projects. Works at small to mid-scale, but large industrial setups require careful automation and biosecurity.

- Biochar: Flexible from small farm kilns to industrial-scale pyrolysis plants. Easier to scale up than BSFL because the process is machine-driven rather than biology-dependent.

Market Maturity

- BSFL: Insect protein and oil are growing markets, but still relatively niche. Strong adoption in aquaculture and pet food, slower in poultry and livestock due to regulations. Frass fertilizer markets are less formal but expanding.

- Biochar: Established soil amendment market, with additional growth in carbon credit systems. International standards (IBI, EBC) make biochar more accepted globally as a recognized product.

Risks and Resilience

- BSFL Risks: Sensitive to temperature and humidity changes. Requires strict hygiene and feedstock quality control. Market risks include dependency on regulation for insect-based feed approval.

- Biochar Risks: Requires consistent biomass supply and energy input. Lower biological risks, more robust under diverse conditions. Storage and transport are simple since biochar is stable and lightweight.

Synergies: When Two Are Better Than One

BSFL and biochar do not have to compete, they can complement each other:

- Adding 5–20% biochar to BSFL feedstock can boost larval yields by up to 195%, improve frass quality, and cut composting time from months to just weeks (PLOS One).

- BSFL residue (frass) can be pyrolyzed to create safe, pathogen-free biochar, adding another revenue stream (ResearchGate).

Side-by-Side Comparison

Factor | BSFL Bioconversion | Biochar Production |

Speed | Days for waste reduction | Minutes to hours plus prep |

Main Outputs | Protein, oils, frass fertilizer | Biochar, syngas, bio-oil |

GHG Impact | Cuts methane, reduces landfill emissions | Long-term carbon sequestration, N₂O ↓ ~80% |

Best Feedstocks | Wet food waste, manure | Woody residues, crop waste, BSFL residue |

Market Value | Feed ingredients, fertilizer | Soil amendment, carbon credits, filtration |

CapEx / OpEx | Moderate upfront, higher labor ongoing | Higher upfront, lower labor ongoing |

Scalability | Effective for small to medium projects | Easily scalable to large industrial plants |

Market Maturity | Growing but niche, regulation-dependent | Established, supported by global standards |

Risks | Biological sensitivity, market regulation | Feedstock and energy dependency, otherwise stable |

Hybrid Options | Works better with biochar in feedstock | Can pyrolyze BSFL residue |

Decision Guide

- Choose BSFL if your waste is mostly wet organics, you want fast processing, and you can sell insect protein or fertilizer locally.

- Choose Biochar if you handle woody or agricultural residues, seek carbon credits, or want long-term soil health improvements.

- Combine Both if you have diverse waste streams. Use BSFL for food waste, biochar for residues, and maximize value through synergy.

Final Word

Both BSFL and biochar are powerful tools for a circular, low-carbon economy. The choice depends less on which is better and more on what kind of waste you have, what products your markets value, and what environmental goals you prioritize. Sometimes, the smartest move is not to choose, but to combine.

Got questions?