Sustainable Concrete Bricks Using Waste Glass, Plastic, Biochar, and Foundry Sand (Consolidated Technical Studies, 2023)

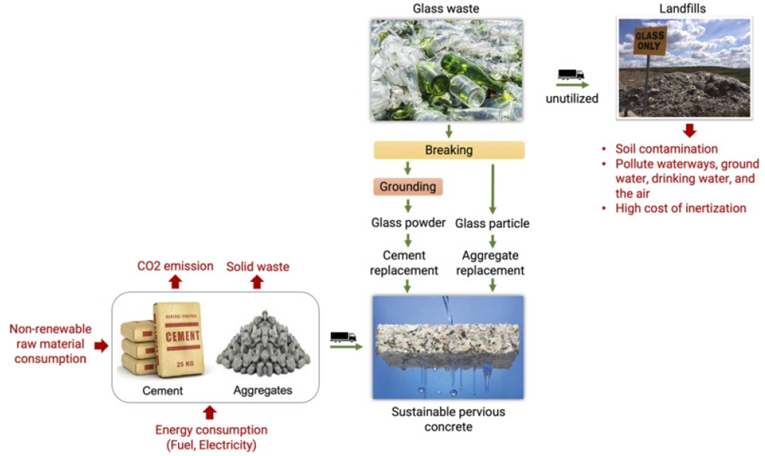

Concrete production is a massive global industry, but it comes with big environmental costs like high CO2 emissions (8% of total global emission) from cement making and the overuse of natural sand and gravel, which harms ecosystems. Waste materials like plastic, glass, and foundry sand often end up in landfills, adding to pollution.

These consolidated technical studies (2023) explore using ground waste glass, plastic, biochar, and foundry sand as partial replacements in concrete bricks. The research tests strength, water absorption, and overall performance, showing how this approach recycles waste while creating durable building materials.

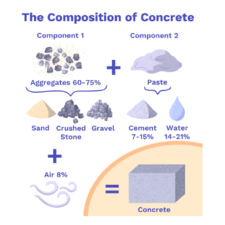

How Sustainable Concrete Works Traditional concrete mixes cement, sand, gravel, and water

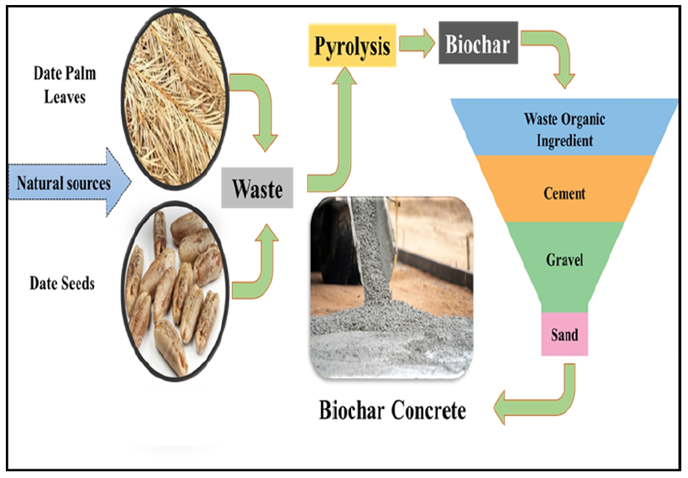

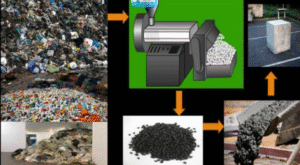

Here, wastes replace parts of those: ground plastic swaps for gravel (coarse aggregate), foundry sand for regular sand (fine aggregate), ground glass powder for cement, and biochar for some cement too. The process starts with collecting and processing wastes– crushing plastic into 10-15 mm flakes, grinding glass to under 75 µm for pozzolanic reactions (which boost strength), producing biochar by heating biomass like farm waste in low oxygen, and using clean foundry sand from metal casting.

Mix ratios are optimized: replace 3-6% fine aggregate with plastic, 10-15% cement with glass, up to 5% cement with biochar, and 5-35% sand with foundry sand. Add a superplasticizer to improve flow without extra water. Dry mix ingredients, add water, pour into molds (like 13x7x5 inches), vibrate to remove air, and cure for 21 days. CO2 curing helps sequester carbon. Tests follow standards like IS 2185 Part 2 for compression and water absorption.

Key Findings: Environmental and Economic Benefits

- Stronger and Lighter Bricks with Waste Additives: The final brick with 10% plastic, 10% glass, and 15% foundry sand hit 23 MPa compressive strength (good for walls) and 2.5% water absorption (resists weathering). Biochar makes concrete lighter and crack-resistant, while glass boosts strength by 5%.

- Big Cuts in CO₂ Emissions and Waste: These mixes reduce cement use (7% of global CO₂ comes from cement), locking carbon in biochar for climate mitigation. They divert plastic/glass from landfills, easing the “sand crisis” (50 billion tons extracted yearly) and preserving rivers/beaches.

- Economic Benefits: Cheaper Materials and New Jobs Using wastes saves 2% on costs—ground glass is cheaper than sand, lighter bricks cut transport/labor expenses. Jobs emerge in waste collection, grinding, and brick making, especially in rural areas turning farm waste into biochar or processing foundry sand.

- Better Insulation and Durability: Biochar and plastic improve thermal/sound insulation, lowering energy bills for heating/cooling. Combined materials resist corrosion, extend building life, and support stucco application for finished walls.

A Waste-to-Wealth Building Solution

These studies show waste-enhanced concrete is a practical, low-carbon alternative to traditional mixes. It reduces emissions, recycles trash, saves resources, and creates affordable, strong bricks. To scale up, focus on quality control, renewable energy for processing, and policies for recycled materials. Waste Free ’23 links this to biochar from trench pyrolysis, BSFL waste processing, and plastic upcycling for full synergies.

Read the Full Studies:

- Experimental Concrete Brick Adding Glass, Plastic and Foundry Sand (Technical Report, 2023).

- Low Carbon Concrete Meta Study (Technical Review, 2023).

Image Sources:

1. https://climatescience.org/simple-construction

2.. https://www.researchgate.net/figure/Production-of-biochar-based-concrete-composite_fig2_367512403

3. https://www.sciencedirect.com/science/article/pii/S2667010022001822

4.https://www.sciencedirect.com/science/article/pii/S2772912524000642

Got questions?