How to Recycle Toothpaste Tubes: Turning Waste into Resources with WasteFree23’s Community Solutions

Are Toothpaste Tubes Recyclable?

Toothpaste tubes (traditionally composed of a blend of plastic and aluminum), have been challenging to recycle. However, thanks to innovations by organizations like WasteFree23.org, it is both possible and beneficial to recycle toothpaste tubes today. Waste Free ’23 presents a solution promoting engagement aimed at dealing with waste at a local level that is sensible, scientific and even profitable, such as in the handling of toothpaste tubes.

Why Recycle Toothpaste Tubes?

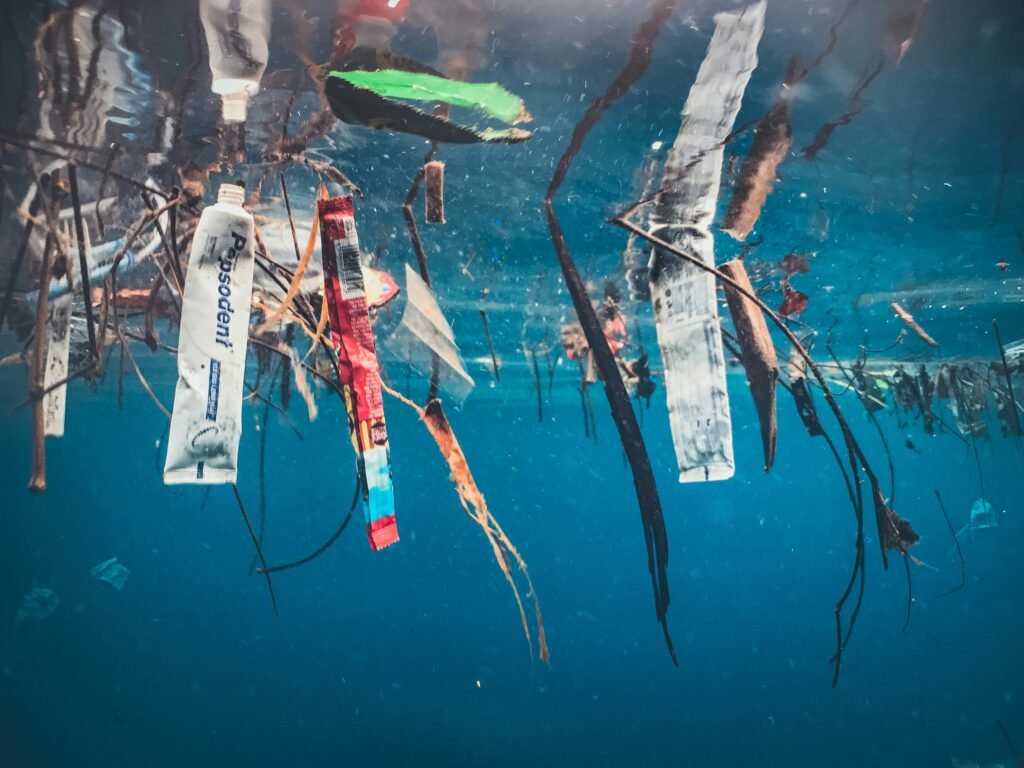

Toothpaste tubes end up in landfills mostly like other waste. Recycling these tubes helps prevent environmental pollution,create employment, and produce valuable items for local communities. In Indonesia, for example, recycled tubes are used to build double roofs, reducing indoor temperatures by up to 10°C. In Kenya, these materials are turned into durable fence posts, preventing deforestation and offering an affordable, sustainable alternative to wood.

How to Recycle Toothpaste Tubes the WasteFree23 Way

Here’s how communities working with Waste Free ‘23 do it safely and efficiently:

1. Collect and clean the Tubes

- Collect Used Toothpaste Tubes: Gather toothpaste tubes from your household or community. Look for programs that accept all brands, including Colgate and sensodyne.

- Clean the tubes: Rinse thoroughly to remove any residue. This helps prevent contamination during recycling.

2. Sort and Identify Plastic Types

- Identify Plastic Type: Different brands use various materials, so identifying the type is essential. Some tubes may carry specific recycling symbols that help you determine this. Check our plastic sorting and recognizing guide.

- Sort by Plastic Type : Grouping similar plastics ensures better quality end products after heat pressing is done.

3. Shred the tubes using a shredder:

- Use a shredder to break down the tubes into small, manageable pieces. Smaller pieces make the recycling process more efficient and improve the final product’s durability.

4. Heat and Press the Plastic

- Place shredded plastic between Teflon sheets.

- Press using a heat press or even a standard iron. Ensure the plastic is evenly heated for about 30 minutes on each side.

- While the plastic is hot, mold it into the desired shape, such as a sheet or pole, and allow it to cool.

Click here to view the different plastic product being made with a heat press.

5. Shape and Solidify the Product: While the plastic is still warm, shape it as needed (e.g., a roofing panel or a fence post).

Now, you have a durable, eco-friendly item ready for use in your community which support local needs, reduce waste, and create jobs.

Why Not All Toothpaste Tubes are Recyclable?

Some old toothpaste tubes contain a mix of materials — mainly layers of plastic and metal — that make them non-recyclable in standard facilities, although companies are now innovating.

Colgate Recyclable Toothpaste Tubes

Colgate has recently launched recyclable toothpaste tubes, designed specifically to be compatible with standard recycling facilities. These tubes are made from HDPE plastic, the same type used in milk jugs, which most WF23 micro recycling centers can process.

Got questions?